The drilling machines market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.7% from 2025 to 2033, driven by increased demand from infrastructure development, mining exploration, oil and gas, automotive, aerospace, and precision manufacturing sectors. Drilling machines serve essential roles across both construction and industrial applications, ranging from high-capacity foundation drilling to fine-component fabrication in metalworking industries. Market growth is supported by technological advancements in automation, multi-spindle designs, and CNC (Computer Numerical Control) integration, enabling higher productivity, precision, and efficiency.

Market Drivers

Expansion in Infrastructure and Urban Development Projects

Ongoing public and private investments in roads, bridges, metro systems, and high-rise buildings are creating steady demand for high-performance drilling equipment. Radial, upright, and gang drilling machines are widely used in metal structure fabrication and assembly in civil engineering and construction. Countries in Asia Pacific, the Middle East, and Latin America are witnessing rapid urbanization, fueling market expansion for foundation and piling machines capable of operating in diverse geotechnical conditions.

Growth in Mining and Resource Exploration Activities

The resurgence of mining activities especially for minerals, rare earth elements, and coal in regions like Africa, Australia, and South America is accelerating the demand for heavy-duty drilling machines. Deep-hole and CNC-guided drilling systems offer the depth and accuracy needed for core sampling and mineral extraction. Drilling rigs that support rapid deployment, digital telemetry, and geomechanical feedback systems are increasingly favored by mining companies aiming to enhance operational safety and resource yield.

Technological Advancement and Automation Integration

The integration of automation, AI-guided tooling, and CNC technologies into drilling machinery is transforming manufacturing and production capabilities. CNC and multiple spindle drilling machines are in high demand within aerospace, automotive, and general manufacturing sectors for producing high-precision holes in metals, composites, and engineered plastics. Additionally, sensor-driven predictive maintenance systems and real-time monitoring dashboards are being adopted to minimize downtime and optimize tool life, particularly in large-scale manufacturing plants.

Market Restraint

High Initial Investment and Skilled Labor Requirements

While drilling machines deliver significant long-term productivity benefits, their initial procurement and installation costs are high, particularly for CNC and multi-axis systems. SMEs often face budgetary constraints in adopting fully automated or high-capacity machines. Furthermore, operating advanced drilling systems requires skilled technicians capable of machine programming, maintenance, and calibration posing a barrier in regions with limited technical education infrastructure. These challenges slow adoption, especially in developing markets.

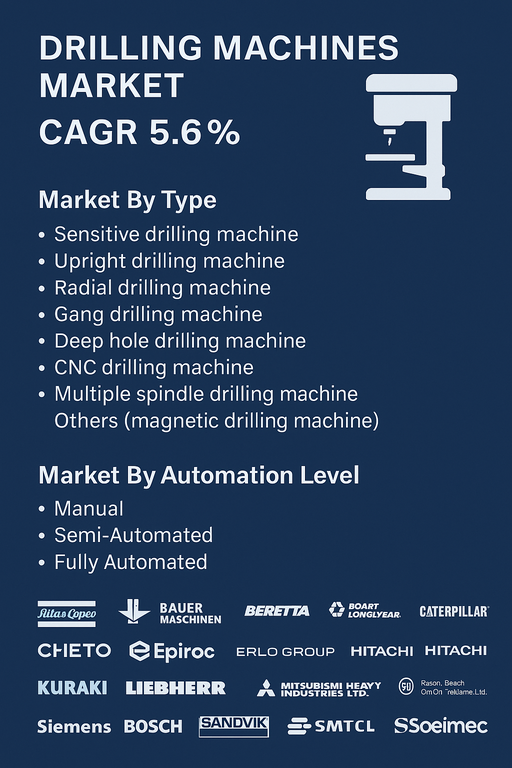

Market Segmentation by Type

The Drilling Machines Market is segmented into Sensitive Drilling Machine, Upright Drilling Machine, Radial Drilling Machine, Gang Drilling Machine, Deep Hole Drilling Machine, CNC Drilling Machine, Multiple Spindle Drilling Machine, and Others (Magnetic Drilling Machine). In 2024, Upright Drilling Machines held the largest market share due to their versatility and extensive use in workshops and small manufacturing setups. Radial and CNC Drilling Machines are gaining strong traction for large-scale operations requiring high precision and depth control. Deep Hole Drilling Machines are increasingly utilized in oil & gas, defense, and aerospace sectors. Multiple Spindle Machines enable simultaneous operations and are used in high-volume production lines, while Magnetic Drilling Machines are preferred for portable applications and structural steel works in field operations.

Market Segmentation by Automation Level

By automation level, the market is segmented into Manual, Semi-Automated, and Fully Automated systems. In 2024, Semi-Automated Drilling Machines led the market due to their cost-effectiveness and adaptability across a wide range of industries. Manual Machines continue to serve entry-level workshops and smaller industrial operations in developing economies due to their low cost and ease of use. Fully Automated Machines, including CNC-based systems, are expected to grow at the highest CAGR during the forecast period as industries shift toward smart manufacturing, lean production, and precision engineering.

Geographic Trends

Asia Pacific dominated the drilling machines market in 2024 and is expected to maintain its lead through 2033, driven by industrialization, rapid infrastructure development, and the presence of large manufacturing bases in China, India, South Korea, and Japan. Government-backed initiatives in India’s “Make in India” and China’s “Belt and Road” infrastructure expansion support machinery deployment. North America followed, with high investments in mining, oil & gas, and advanced aerospace manufacturing facilities, especially in the U.S. and Canada. Europe remains a mature market characterized by automation in precision manufacturing and automotive sectors, led by Germany, Italy, and France. Latin America and Middle East & Africa represent emerging markets, with growth supported by mining exploration, construction of mega infrastructure, and energy sector investments in Brazil, Chile, Saudi Arabia, and UAE.

Competitive Trends

The drilling machines market features a mix of multinational heavy equipment manufacturers and specialized tooling companies. In 2024, Atlas Copco, Caterpillar, Sandvik AB, and Epiroc AB led in surface and underground drilling solutions for mining and construction applications. Mitsubishi Heavy Industries, Hitachi Construction Machinery Ltd, and Liebherr Group offered high-capacity machines for infrastructure and oil & gas. Cheto Corporation SA, KURAKI Co Ltd, and ERLO Group focused on CNC and deep-hole drilling systems tailored for automotive and aerospace component production. Robert Bosch GmbH, Minitool, and Beretta S.r.l. provided versatile machines for light industrial, fabrication, and DIY markets. Chinese manufacturers such as Shenyang Machine Tool Co Ltd, SMTCL, and Dezhou Hongxin Machine Tool Co Ltd supplied cost-competitive solutions for emerging economies. Soilmec S.p.A. and Bauer Maschinen GmbH specialized in foundation drilling and civil infrastructure projects. Strategic alliances, smart machine innovations, and localization of production are expected to shape competitive advantage through 2033.

Historical & Forecast Period

This study report represents analysis of each segment from 2023 to 2033 considering 2024 as the base year. Compounded Annual Growth Rate (CAGR) for each of the respective segments estimated for the forecast period of 2025 to 2033.

The current report comprises of quantitative market estimations for each micro market for every geographical region and qualitative market analysis such as micro and macro environment analysis, market trends, competitive intelligence, segment analysis, porters five force model, top winning strategies, top investment markets, emerging trends and technological analysis, case studies, strategic conclusions and recommendations and other key market insights.

Research Methodology

The complete research study was conducted in three phases, namely: secondary research, primary research, and expert panel review. key data point that enables the estimation of Drilling Machines market are as follows:

Market forecast was performed through proprietary software that analyzes various qualitative and quantitative factors. Growth rate and CAGR were estimated through intensive secondary and primary research. Data triangulation across various data points provides accuracy across various analyzed market segments in the report. Application of both top down and bottom-up approach for validation of market estimation assures logical, methodical and mathematical consistency of the quantitative data.

| ATTRIBUTE | DETAILS |

|---|---|

| Research Period | 2023-2033 |

| Base Year | 2024 |

| Forecast Period | 2025-2033 |

| Historical Year | 2023 |

| Unit | USD Million |

| Segmentation | |

Type

| |

Automation Level

| |

Operation

| |

Structure

| |

Power Source

| |

Application

| |

End Use

| |

Distribution Channel

| |

|

Region Segment (2023-2033; US$ Million)

|

Key questions answered in this report