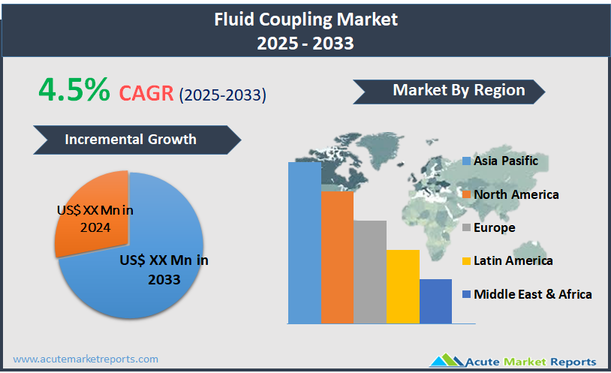

Fluid coupling is a hydrodynamic device used to transmit rotating mechanical power. The fluid coupling market is experiencing steady growth, driven by its critical application in industries such as mining, material handling, automotive, and power generation. The key attribute of fluid couplings, their ability to prevent mechanical overload and reduce torsional vibrations, makes them indispensable in operations where power transmission efficiency is crucial. The growth of industries that require heavy-duty machinery and the need for operational efficiency in power transmission are significant factors contributing to the market expansion. With a compound annual growth rate (CAGR) of 4.5%, the market is expected to continue growing, driven by technological innovations and increasing demand for energy-efficient devices. Manufacturers are focusing on enhancing the durability and efficiency of fluid couplings to cater to the evolving needs of high-performance industrial machinery.

Driver: Increasing Demand in Heavy Industries

The expansion of heavy industries such as mining, construction, and metal processing significantly drives the fluid coupling market. Fluid couplings are essential in machinery used in these industries due to their ability to control the start-up torque and reduce mechanical stress on power transmission systems. This capacity is particularly crucial in applications involving heavy loads and variable speeds, where mechanical shocks can lead to equipment failures. As global industrialization progresses, the demand for equipment that ensures operational reliability and efficiency continues to rise. The adoption of fluid couplings enhances the longevity and performance of machinery, thus supporting the market's growth. For example, in the mining sector, where equipment downtime can result in substantial financial losses, the use of fluid couplings for conveyor belts and transport vehicles has become standard to mitigate such risks.

Opportunity: Renewable Energy Sector

The renewable energy sector presents a burgeoning opportunity for the fluid coupling market. With the global shift towards sustainable energy practices, industries are investing in technologies that optimize power generation efficiency and minimize energy loss. Fluid couplings play a vital role in wind turbines and hydroelectric power plants by providing load management capabilities and protecting against torque surges. This application is essential for maintaining the stability of power transmission systems and enhancing the durability of

Market Segmentation by Product Type

The fluid coupling market is segmented into constant-fill fluid couplings and variable speed fluid couplings. Constant-fill fluid couplings dominate the market in terms of revenue due to their widespread use in heavy machinery and industrial applications where robust and reliable power transmission is crucial. These couplings are preferred for their durability and simplicity, making them ideal for applications involving complex machinery operations under consistent operational conditions. On the other hand, variable speed fluid couplings are projected to exhibit the highest Compound Annual Growth Rate (CAGR) from 2025 to 2033. This growth is driven by the increasing demand for energy efficiency and precise control in industrial processes. Variable speed couplings offer the ability to adjust the coupling's slip rate according to process requirements, enhancing system efficiency and reducing energy consumption, which is increasingly valued in sectors striving for sustainability and cost reduction.

Market Segmentation by Application

In terms of application, the fluid coupling market is segmented into centrifuges & reciprocating pumps, mixers & agitators, crushers & grinding mills, cranes & conveyors, and others. The segment involving cranes & conveyors accounts for the highest revenue within the market, given the critical role of fluid couplings in managing load and torque in material handling operations, which are prevalent across various industrial sectors. Fluid couplings enhance the operational efficiency and safety of these systems, making them indispensable in sectors like manufacturing, mining, and logistics. Meanwhile, the crushers & grinding mills segment is expected to witness the highest CAGR through the forecast period. This anticipated growth stems from the expansion of the mining and construction industries, where crushers and mills are essential for processing materials. The ability of fluid couplings to provide shock absorption and load distribution in these heavy-duty applications contributes significantly to their increased adoption, driving market growth in this segment.

Geographic Segment

The fluid coupling market exhibits distinct geographic trends, with Asia-Pacific leading in terms of both revenue and the highest Compound Annual Growth Rate (CAGR) forecasted from 2025 to 2033. In 2024, Asia-Pacific's dominance was driven by rapid industrial growth, expansion of manufacturing sectors, and increased investments in infrastructure projects across countries like China, India, and Southeast Asia. This region benefits from a robust increase in activities in sectors such as mining, construction, and energy, which heavily utilize fluid couplings for efficient power transmission. Moreover, the region's focus on enhancing industrial automation and adopting energy-efficient technologies contributes to the sustained growth. The demand in Asia-Pacific is expected to continue its upward trajectory, driven by ongoing industrialization and urbanization.

Competitive Trends and Top Players

In 2024, the fluid coupling market was characterized by the strategic activities of leading players such as Premium Transmission, Fluiodmat Limited, Regal Rexnord Corporation, Flender, Voith GmbH & Co. KGaA, The VULKAN Group, Elecon Engineering Company Limited, Wichita Clutch, Transfluid Industrial & Marine, and Nara Corporation. These companies collectively focused on innovation, geographic expansion, and enhancing product portfolios to meet the diverse requirements of the industrial sectors. For instance, Voith GmbH & Co. KGaA continued to innovate in the field of variable speed fluid couplings, catering to the demand for energy efficiency. Similarly, Flender and Regal Rexnord expanded their market presence through strategic partnerships and acquisitions, aiming to broaden their technological capabilities and strengthen their global footprints. Premium Transmission and The VULKAN Group emphasized on developing high-performance and durable fluid coupling solutions to ensure reliability in heavy-duty applications. From 2025 to 2033, these companies are expected to intensify their focus on emerging markets, where the demand for advanced industrial machinery is on the rise. Key strategies are anticipated to include further technological advancements in fluid coupling products, expansion into new markets, and the adoption of sustainable practices in manufacturing to align with global environmental standards. These efforts are projected to bolster their positions in the global market while addressing the evolving needs of their industrial customers.

Historical & Forecast Period

This study report represents analysis of each segment from 2023 to 2033 considering 2024 as the base year. Compounded Annual Growth Rate (CAGR) for each of the respective segments estimated for the forecast period of 2025 to 2033.

The current report comprises of quantitative market estimations for each micro market for every geographical region and qualitative market analysis such as micro and macro environment analysis, market trends, competitive intelligence, segment analysis, porters five force model, top winning strategies, top investment markets, emerging trends and technological analysis, case studies, strategic conclusions and recommendations and other key market insights.

Research Methodology

The complete research study was conducted in three phases, namely: secondary research, primary research, and expert panel review. key data point that enables the estimation of Fluid Coupling market are as follows:

Market forecast was performed through proprietary software that analyzes various qualitative and quantitative factors. Growth rate and CAGR were estimated through intensive secondary and primary research. Data triangulation across various data points provides accuracy across various analyzed market segments in the report. Application of both top down and bottom-up approach for validation of market estimation assures logical, methodical and mathematical consistency of the quantitative data.

| ATTRIBUTE | DETAILS |

|---|---|

| Research Period | 2023-2033 |

| Base Year | 2024 |

| Forecast Period | 2025-2033 |

| Historical Year | 2023 |

| Unit | USD Million |

| Segmentation | |

Product Type

| |

Application

| |

End-use

| |

Distribution Channel

| |

|

Region Segment (2023-2033; US$ Million)

|

Key questions answered in this report