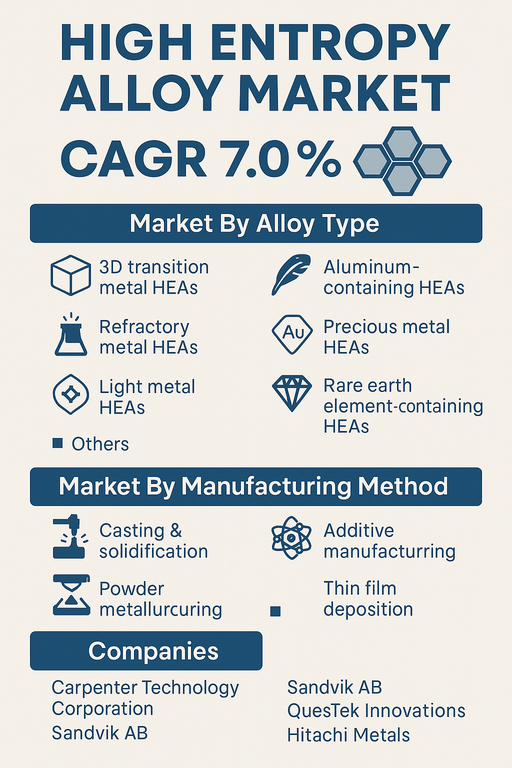

The global high entropy alloy market is projected to grow at a CAGR of 7.0% between 2025 and 2033. Growth is driven by increasing adoption in aerospace, automotive, electronics, and energy sectors due to HEAs’ superior strength, wear resistance, corrosion protection, and thermal stability. Advancements in alloy design, process optimization, and lightweight engineering across diverse industries are also boosting demand. Rising interest in additive manufacturing and powder metallurgy techniques further supports long-term market growth.

Market Drivers

Rising requirements for high-performance materials capable of withstanding extreme environments encourage adoption of HEAs. Increased R&D investments into lightweight and sustainable materials across automotive, energy, and aerospace sectors support market expansion. Adoption of additive manufacturing and powder-based processes enhances flexibility in alloy design, making HEAs attractive for customized components.

Market Restraint

Despite strong demand, the market faces challenges related to high production costs and limited scalability of some advanced manufacturing processes. Material uniformity, complex process optimization, and a need for specialized expertise may also restrict broad commercialization and usage of HEAs in some industries.

Market By Alloy Type

By alloy type, refractory metal HEAs accounted for the largest share in 2024 owing to demand for temperature-resistant materials for turbine engines and energy applications. 3D transition metal HEAs also showed strong uptake across automotive and electronics due to their cost-effective properties and balanced strength-ductility profiles. Light metal HEAs and aluminum-containing HEAs are projected to register higher CAGR as manufacturers target weight reduction in structural and transport applications. Precious metal HEAs and rare-earth-element-containing HEAs continue to serve niche sectors due to unique magnetic, thermal, and corrosion-resistant properties.

Market By Manufacturing Method

By manufacturing method, powder metallurgy led the market in 2024 driven by broad scalability and precise composition control. Additive manufacturing is anticipated to register the highest CAGR owing to rapid prototyping, design flexibility, and increased cost-efficiency. Casting & solidification techniques will continue to hold a significant share across traditional industrial processes. Thin-film deposition is projected to grow steadily as coating requirements rise in electronics and semiconductor applications.

Geographic Trends

North America and Europe led the market in 2024 owing to strong R&D initiatives and established aerospace and energy industries. The Asia Pacific region is expected to record the highest CAGR, driven by rapid industrialization, increased infrastructure investments, and expanding automotive and electronics production capacity across China, India, Japan, and South Korea. Latin America and Middle East & Africa present incremental opportunities as regional manufacturers modernize their production processes and explore advanced material adoption.

Competitive Trends

The competitive landscape is characterized by global players including Carpenter Technology Corporation, Sandvik AB, QuesTek Innovations, Hitachi Metals, and Allegheny Technologies Incorporated. Companies focus on new material formulations, sustainable alloy development, and customized product offerings to meet customer-specific requirements. Strategic partnerships with research institutes, joint ventures for scaling additive manufacturing capacity, and continuous innovation in processing techniques will help key players strengthen their footprint and address evolving application demands in the high entropy alloy market.

Historical & Forecast Period

This study report represents analysis of each segment from 2023 to 2033 considering 2024 as the base year. Compounded Annual Growth Rate (CAGR) for each of the respective segments estimated for the forecast period of 2025 to 2033.

The current report comprises of quantitative market estimations for each micro market for every geographical region and qualitative market analysis such as micro and macro environment analysis, market trends, competitive intelligence, segment analysis, porters five force model, top winning strategies, top investment markets, emerging trends and technological analysis, case studies, strategic conclusions and recommendations and other key market insights.

Research Methodology

The complete research study was conducted in three phases, namely: secondary research, primary research, and expert panel review. key data point that enables the estimation of High Entropy Alloy market are as follows:

Market forecast was performed through proprietary software that analyzes various qualitative and quantitative factors. Growth rate and CAGR were estimated through intensive secondary and primary research. Data triangulation across various data points provides accuracy across various analyzed market segments in the report. Application of both top down and bottom-up approach for validation of market estimation assures logical, methodical and mathematical consistency of the quantitative data.

| ATTRIBUTE | DETAILS |

|---|---|

| Research Period | 2023-2033 |

| Base Year | 2024 |

| Forecast Period | 2025-2033 |

| Historical Year | 2023 |

| Unit | USD Million |

| Segmentation | |

Alloy Type

| |

Manufacturing Method

| |

Property

| |

Application

| |

End Use Industry

| |

|

Region Segment (2023-2033; US$ Million)

|

Key questions answered in this report