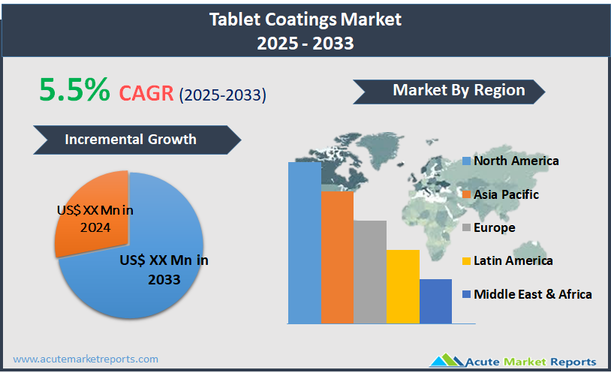

Tablet coatings are thin layers of a mixture of materials applied to the exterior of a tablet to achieve specific benefits such as improving the organoleptic properties (taste and smell), protecting the core ingredients from the environment, controlling the release of a drug, and enhancing the appearance of tablets. These coatings can be composed of various substances including polymers, plasticizers, pigments, and fillers. The tablet coating process is a critical step in pharmaceutical manufacturing, as it aids in the stability, efficacy, and patient compliance of oral dosage forms. The tablet coatings market is projected to grow at a compound annual growth rate (CAGR) of 5.5%. This growth is propelled by the ongoing advancements in coating technologies and the expanding global pharmaceutical industry. Emerging markets, in particular, present significant growth opportunities as healthcare infrastructures improve and access to medications increases. The drive towards generic drugs is another factor contributing to market growth, as manufacturers seek cost-effective yet reliable coating solutions to enhance the marketability and functionality of generic formulations.

Increasing Demand for Controlled Release Formulations Drives Market Growth

The primary driver propelling the tablet coatings market is the increasing demand for controlled release formulations in the pharmaceutical industry. Controlled release coatings are essential for improving drug efficacy by ensuring the active pharmaceutical ingredient (API) is released at the correct site in the digestive tract and over a desired period. This not only optimizes the therapeutic effect but also enhances patient compliance by reducing the frequency of dosage. The growing prevalence of chronic diseases, which require long-term medication management, has spurred the development and uptake of these sophisticated coating systems. As pharmaceutical companies continue to invest in the development of drugs that offer improved patient outcomes and adherence, the need for advanced coating technologies that support these goals becomes more critical. This trend is especially prominent in the management of chronic conditions like diabetes and cardiovascular diseases, where controlled drug release is beneficial.

Expansion into Emerging Markets Presents Opportunities

Emerging markets represent a significant opportunity for the expansion of the tablet coatings market. These regions are experiencing rapid growth in their healthcare sectors due to increasing economic prosperity, improvements in healthcare infrastructure, and a growing middle class that can afford better healthcare services. Countries like India, China, and Brazil are seeing an increase in pharmaceutical manufacturing activities as companies look to capitalize on lower production costs and expanding local markets. The regulatory environments in these countries are also evolving, becoming more aligned with international standards, which encourages foreign investment and technology transfer. For tablet coating manufacturers, these markets offer a fertile ground for establishing production facilities and distribution networks to cater to the local and regional pharmaceutical industries. This expansion is not only driven by the cost advantages but also by the growing demand for pharmaceutical products in these regions, which are becoming more aware and receptive to advanced drug delivery systems and high-quality medication.

High Costs of Advanced Coating Technologies Limit Market Growth

Despite the advantages offered by advanced tablet coating technologies, their high costs pose a significant restraint to the market's growth. The development and implementation of innovative coatings such as polymer-based or functional coatings require substantial investment in research and development as well as in upgrading manufacturing facilities. For many pharmaceutical manufacturers, especially in less developed countries, these costs are prohibitive. The economic barrier is heightened by the need for specialized equipment and expertise to apply these advanced coatings effectively. Additionally, the cost of raw materials for high-quality coatings can be significant, further straining the financial resources of manufacturers. This economic challenge is particularly acute for smaller players in the pharmaceutical industry who must compete with larger, more financially robust companies that can more easily absorb these initial costs.

Regulatory Compliance Challenges Industry Participants

The tablet coatings industry faces significant challenges in meeting diverse and sometimes stringent regulatory requirements across different global markets. Regulatory compliance is crucial for manufacturers to ensure their products can be sold in international markets, but adhering to these standards involves extensive testing and documentation. Each market, from the United States and European Union to emerging economies, has its own set of regulations governing the composition, safety, and efficacy of tablet coatings. Keeping up with these regulations, particularly as they evolve to keep pace with technological advancements and medical discoveries, requires continuous investment in regulatory expertise and processes. This ongoing requirement can delay product launches and increase costs, affecting the ability of companies to compete effectively and innovate within the coatings space.

Market Segmentation by Polymer Type

The tablet coatings market is segmented based on polymer types into cellulosic polymers, vinyl derivatives, acrylic polymers, and others. Among these, acrylic polymers are anticipated to generate the highest revenue due to their widespread use in pharmaceutical coatings, driven by their excellent film-forming properties and versatility in both aqueous and non-aqueous solvents. Acrylic polymers are preferred for their ability to facilitate controlled release mechanisms and enhance the stability and appearance of tablets. On the other hand, cellulosic polymers are expected to exhibit the highest CAGR. This growth is fueled by their biocompatibility and the ease with which they can be formulated to meet specific drug release profiles. Cellulosic polymers, such as hydroxypropyl methylcellulose, are increasingly used in modern pharmaceuticals for their non-toxic and cost-effective properties, making them ideal for sustained-release formulations. The growing demand for sophisticated drug delivery systems in the pharmaceutical industry continues to drive innovations and developments in cellulosic coatings, capitalizing on their environmental and regulatory advantages over synthetic alternatives.

Market Segmentation by Type of Coating

In terms of the types of coatings, the market is divided into film-coated tablets, sugar-coated tablets, enteric-coated tablets, gelatin-coated tablets, and others. Film-coated tablets hold the distinction of generating the highest revenue within this segment. The popularity of film coatings can be attributed to their cost-effectiveness, patient compliance, and ability to significantly enhance the tablet's physical and chemical stability. Film coatings also offer versatility in terms of aesthetics, allowing for a wide range of colors and finishes that make tablets more appealing to consumers. In contrast, enteric-coated tablets are projected to register the highest CAGR due to their critical role in protecting active ingredients that are sensitive to stomach acids and ensuring the release of the active ingredients in the intestine, which is ideal for maximizing drug absorption and efficacy. This type of coating is essential for drugs that can be irritating to the stomach or are intended for targeted release in the lower gastrointestinal tract. The rising demand for targeted drug delivery systems and the ongoing development of new pharmaceutical formulations are key drivers for the growth of the enteric coating segment, reflecting broader trends towards more specialized and patient-centric treatments in healthcare.

Geographic Segment

In 2024, North America emerged as the region with the highest revenue percentage, supported by an established healthcare infrastructure, high awareness of mobility assistance products, and stringent regulatory standards ensuring product quality and safety. The region's market is also bolstered by a significant aging population and high prevalence of conditions requiring mobility aids. However, the Asia Pacific region is expected to witness the highest CAGR from 2025 to 2033. This anticipated growth is due to increasing healthcare expenditures, rising awareness of mobility solutions, and growing elderly populations in countries such as China and India. Improvements in healthcare infrastructure and increased local manufacturing capabilities to reduce costs are also factors expected to drive demand in the Asia Pacific market during the forecast period.

Competitive Trends and Key Strategies

The competitive landscape in 2024 featured key players such as Invacare Corporation, Sunrise Medical LLC, Ottobock, Permobil, Pride Mobility Products Corp, Drive Medical, GF Health Products, Inc., 21st Century Scientific, Inc., Karman Healthcare, Hoveround, and other prominent players. These companies focused on innovation and geographical expansion to enhance their market presence. Strategies such as the development of lightweight and more technologically advanced mobility aids that offer greater comfort and convenience were prevalent. In addition, strategic mergers and acquisitions were common among the top players, aiming to expand their product portfolios and access new markets. For the forecast period of 2025 to 2033, these companies are expected to increasingly invest in smart technologies, incorporating features such as GPS navigation, Wi-Fi, and Bluetooth connectivity, which cater to the rising consumer demand for more integrated and user-friendly products. Furthermore, there is an expected increase in initiatives targeting emerging markets, where they plan to leverage rising healthcare spending and the rapidly growing demand for mobility aids. Investments in improving after-sales services and expanding distribution networks are also anticipated to be key strategies moving forward, enhancing overall customer satisfaction and retention.

Historical & Forecast Period

This study report represents analysis of each segment from 2023 to 2033 considering 2024 as the base year. Compounded Annual Growth Rate (CAGR) for each of the respective segments estimated for the forecast period of 2025 to 2033.

The current report comprises of quantitative market estimations for each micro market for every geographical region and qualitative market analysis such as micro and macro environment analysis, market trends, competitive intelligence, segment analysis, porters five force model, top winning strategies, top investment markets, emerging trends and technological analysis, case studies, strategic conclusions and recommendations and other key market insights.

Research Methodology

The complete research study was conducted in three phases, namely: secondary research, primary research, and expert panel review. key data point that enables the estimation of Tablet Coatings market are as follows:

Market forecast was performed through proprietary software that analyzes various qualitative and quantitative factors. Growth rate and CAGR were estimated through intensive secondary and primary research. Data triangulation across various data points provides accuracy across various analyzed market segments in the report. Application of both top down and bottom-up approach for validation of market estimation assures logical, methodical and mathematical consistency of the quantitative data.

| ATTRIBUTE | DETAILS |

|---|---|

| Research Period | 2023-2033 |

| Base Year | 2024 |

| Forecast Period | 2025-2033 |

| Historical Year | 2023 |

| Unit | USD Million |

| Segmentation | |

Polymer Type

| |

Type of Coating

| |

End-user

| |

|

Region Segment (2023-2033; US$ Million)

|

Key questions answered in this report